Pipe joints - Definition and Types

What is a pipe joint?

Pipe joints are essential for any plumbing system because they cannot have a continuous length of pipe to a pipe network. These joints can create or break pipeline systems, depending on their durability as a result of the technology used to form the joint.

The different materials for the pipes used in the pipeline industry depend on the need and type of product to be delivered through the pipe.

Pipe joint type:-

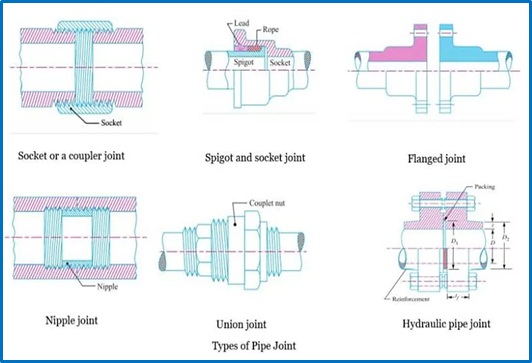

1. Socket or coupler joint

The most common way to join pipes is to use sockets or couplers. A socket is a small piece of internal pipe thread. This type of joint is mainly used for pipes carrying water at low pressure, where overall size is of utmost importance.

In order to prevent leakage, jute or hemp wound around the threads at the end of each pipe. This type of joint mostly used for pipes carrying water at low pressure and where the overall smallness of size is most essential.

2. Nipple joint

In this type of joint, a nipple refers to a small piece of pipe that is threaded at the end of each pipe's internal thread.

3. Union joint

To disconnect a pipe joined by a socket, it is necessary to unscrew the pipe at one end, which is sometimes inconvenient when the pipe is elongated. The union joint provides the function of dismantling the pipe by simply loosening the coupler nut.

4. Spigot and socket joint

It is mainly used for pipes buried in the ground. Some pipelines are laid out as straight as possible. One of the important characteristics of these joints is their flexibility because they adapt to small-scale changes in the movement of the ground caused by climate and other conditions.

In this type of joint, the spire end of one pipe fits the socket end of the other pipe. The remaining space between the two is filled with jute rope and ring of lead. When the lead hardens, it is caulked firmly.

5. Expansion joint

Pipes carrying steam at high pressure are usually joined by expansion joints. These joints are used in steam pipes to resist expansion and contraction of the pipeline due to temperature changes.

To allow for variations in length, the steam pipe is not rigidly fixed, but supported on rollers. Rollers can be placed on wall brackets, hangers or floor stands. This makes Expansion joints useful for long pipelines.

This pipe bend rises in either direction and can easily accommodate small movements of the attached actual pipe end.

6. Flange joint

Flange joints are one of the most widely used pipe joints. Flanged joints can be made of flanged castings in which pipes or loose flanges are welded or threaded.

Flanges are connected via bolts. Flanges are standardized to pressures up to 2 N/mm2 and flange faces are machined to ensure correct alignment of the pipe.

The joint can be leak-tight by placing a gasket of soft material, rubber or canvas between the flanges. The flange is made thicker than the pipe wall for strength.

7. Hydraulic pipe joint

The type of joint has an oval flange and is secured with two bolts. Oval flanges are typically used for small pipes with a diameter of 175 mm. Flanges are usually cast integrally with the pipe end.

These joints are used to carry fluid pressures from 5 to 14 N/mm2 and high pressures are found in hydraulic applications such as rivets, presses, lifts, etc.

![Saudi Aracmo GI 7.028 (SA-9466) Mobile Crane Operator Daily Inspection Checklist -2022 [PDF]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjjqlj8kIuErWV-fogjqZWkEjkXJW1cUjZgxYuYDzZrePGV1IR53ShWP2cfij4S5DbquaoCZmVrI4HXLPS3J1D0Uo3KQ8EcOKJGNLJ0jt4jQQm7WBQY9EMjTEmmqpHaU2_U7cKrJOJgMOInJiMy-MHQOqO6AuqEsJXy3e4nxenuKKf57H8mwyz3kUXgafU/s72-c/dsdsdsdsds_001-qcskills-7.028.jpg)

No comments:

Post a Comment